Equipment and process of stone production line

Simple stone production line process: large stone → vibrating feeder → jaw crusher → belt conveyor → impact crusher (optional) → belt conveyor → sand making machine → belt conveyor → circular vibrating screen → belt Conveyor → finished product silo.

Commonly used equipment are:

Large stone crushing equipment: jaw crusher, impact crusher, etc.

Stone shaping and crushing equipment: the third generation sand making machine, impact sand making machine, cone crusher, double roller sand making machine, etc.

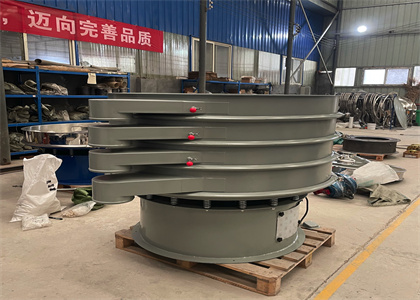

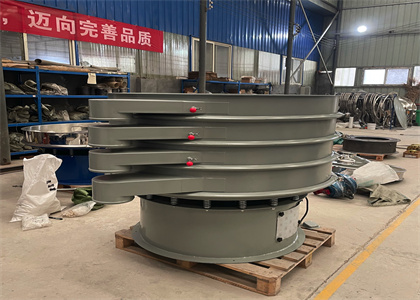

Stone screening and conveying equipment: vibrating feeder, belt conveyor, circular vibrating screen, etc.

The vibrating screen screens crushed stones of different particle sizes to complete the processing work

The output granularity of the stone production line is different, which can be adjusted according to the user's requirements. Generally, the output is screened into three or four particle size grades: 20mm-30mm, 10mm-20mm, 5mm-10mm, fine sand below 5mm, etc. The stones are finely crushed and then transported to the circular

vibrating screen for screening. After screening, they are transported to different finished product silos according to different particle sizes.

Henan Chunying Environmental Protection Equipment Co., Ltd. is a source factory that produces directly to users. Welcome to contact us.