The method for producing red iron oxide from iron concentrate powder mainly includes primary screening, primary grinding, magnetic separation, drying, fine grinding, oxidation roasting, cooling, fine grinding, classification, magnetic separation and packaging.

It can produce high-quality iron oxide red products. This technology has low investment, quick results and broad market prospects, and is especially suitable for the production of small and medium-sized enterprises. As a grinding equipment manufacturer, Xinxiang Dayong can provide a complete set of equipment for this technology, which has the characteristics of simple process, short process and strong continuity, and can meet the requirements of industrial production with high output and low cost. The product has the advantages of high purity, fine particle size and narrow particle size distribution. Today, I will explain the steps of producing iron oxide red from iron concentrate powder and what grinder is needed.

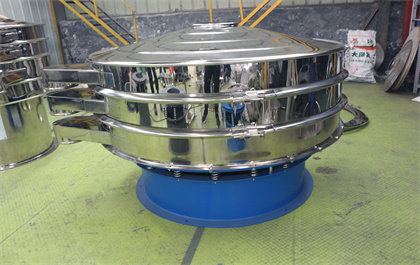

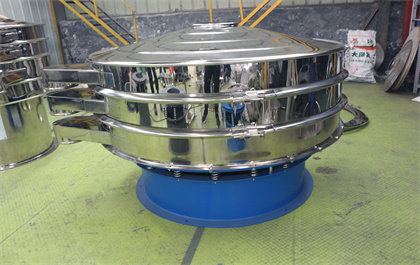

A, the iron ore concentrate is screened through a 60-mesh

rotary vibro sieve;

B. Use Raymond machine to grind iron ore concentrate powder, and its particle size should be controlled within the range of -800~1200 mesh;

C. The ground iron ore concentrate powder is subjected to multi-stage magnetic separation with a series of magnetic separation columns to further separate colored substances. The magnetic field strength is 2~14KA/m, the total iron content is ≥70%, and the water content is <5%;

D. Use a rotary double-layer drying oven for drying. The drying temperature is 350~650℃, and the water content is less than 0.5%;

E. Ultra-fine vertical grinding, the average particle size of mineral powder is controlled at 8-12μm;

F. Enter the rotary roasting furnace for roasting treatment, and strengthen blowing at the same time. When the temperature of the exhaust gas at the furnace tail is lower than 400°C, it is discharged into the atmosphere through two series-connected cyclone separators, bag filter and water curtain, and the heated air enters the enhanced blast system;

G. After the converted iron oxide red powder is roasted with oxygen, it is cooled in a water-cooled chute, sieved by a rotary vibrating screen, and then enters a supersonic ultra-fine airflow crushing and classifying machine. Continuous ultrafine crushing and classification, the average particle size of the product is controlled at 0.1~4μm. The production process of fine powder is completed by magnetic separation and packaging.