Take you to understand the z-type bucket elevator, TH-type bucket elevator and vertical bucket elevator

Bucket elevator is a widely used transportation equipment, especially in such occasions as grain storage, grain and oil and feed processing, considering that the operation target of bucket elevator is mainly granular and powdery materials, so the demand In addition to some primary components, it is also necessary to set up a cleaning device for it to ensure that the material can be completely discharged.

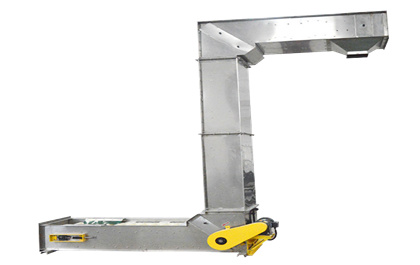

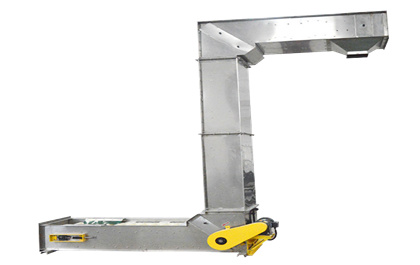

The material cleaning device of the bucket elevator is composed of three parts: the material cleaning plate, the quick clamp, and the detachable shaft. Due to the use of the quick clamp and the detachable shaft, the opening and closing time of the material cleaning plate can be reduced, and the original plate is eliminated. jamming problem.

1.

Z type bucket elevator

Z-type bucket elevator is a commonly used lifting equipment in the industry. Many people who have been in contact with it may not know it very well. We can only use it when we have mastered the sealing structure of the bucket elevator. to operate.

The sealing structure of the current bucket elevator is relatively simple, which is helpful to the mechanical processing to a large extent. In order to ensure the sealing structure of the bucket elevator, it can be conveniently installed and used, especially when dealing with small axial space. The gland needs to be rotated with the help of the fastening screw, and the packing in the calyx is in contact with the surface of the follower shaft, and they are all in a relatively static state at this time. After the mineral powder or material penetrates into the gland, considering that there is no obvious relative movement between the shaft and the filler, it needs to rely on the gap between the filler and the shaft to flow out. Therefore the mineral powder or material cannot flow out of the gap, and then the shaft surface will not be abraded by the mineral powder or material.

The degree of packing compression between the pressure cover and the filling box needs to be adjusted conveniently and simply by means of fastening screws, and then in the process of ore powder or material leakage, only a corresponding degree of wear will occur between the groove surface and the packing, and other parts will not Significant wear and tear occurs. The screw part of the pressure cap is installed in the box. When the pressure cover and the shaft rotate, the ore powder or material squeezed into the screw can be thrown in the opposite direction. In the process, only a small amount of ore powder or material flows into the filling place through the spiral flow, which can ensure that Reduce the amount of leaked ore or material to a great extent.

2.

TH bucket elevator

TH bucket elevator has become the main equipment used in transportation machinery and equipment, because the bucket elevator has a small body, a small footprint, stable operation, good applicability, good air tightness and less dust except for the shell structure.

.jpg)

1. The main function of the bucket elevator is to transport our industry, minerals, cement, coal and other materials with little grindability upward.

2. There are also many transportation methods for bucket elevators, including tapes and chains. Due to the different materials to be transported, different traction components are used. Due to the different traction parts of the bucket elevator, the vertical speed is generally 1, 0m-1, 5m/s.

3. When the bucket elevator is running, the conveying speed should not be too fast. At this time, the reason why the reducer is needed, because once the speed is too fast, the equipment will run unstable, the vibration will be strong, and there will be a drop phenomenon in the process of conveying materials, which is the so-called material backflow. To avoid this, inside the bucket elevator, if the speed is too high, the loading hopper will not be full when scooping up the material. So when we choose the bucket elevator, we can choose our specifications. We don't need to care about the vertical speed of the bucket elevator, because when the customer buys the bucket elevator, all manufacturers have already set it up, which can achieve our goal of stable transportation and standard output.

3. Vertical bucket elevator

.jpg)

When the vertical bucket elevator is in use, various problems may be encountered, one of which is the friction between the hopper and the shell.

The phenomenon that the hopper touches the shell is often a sign that the traction chain and belt are falling off, causing major equipment accidents. If the tension of the traction chain and belt is insufficient, or the extension of the newly replaced chain and belt due to early wear is far greater than the extension of the middle and late wear, or the lower redirection shaft is not adjusted in time, the hopper will damage the shell.

According to the vertical bucket elevator manufacturer, it is relatively simple to deal with such failures. As long as the tension of the traction chain and belt can be adjusted in time, and the appropriate length of the chain and belt can be cut as needed, the adjustment will be more convenient.

The new sealing structure is relatively simple, which is of great help to the machine. In order to ensure the sealing structure of the vertical bucket elevator, especially in the case of small axial space, the installation and use of the elevator are convenient and simple.

Then the cover plate needs to be rotated with the shaft by fastening screws, and the filler in the cover plate is in contact with the surface of the moving shaft and is in a relatively static state. After the mineral powder and materials pass through the gland, there is no obvious relative movement between the shaft and the filler.

The gap between the filling material and the shaft needs to flow out, so the mineral powder and materials will not flow out from the gap of the vertical bucket elevator, and the mineral powder and materials will not wear the surface of the shaft. The degree of compression of the filling material between the lid and the filling box needs to be adjusted simply by tightening the screws. In addition, only a small amount of wear will occur between the groove surface and the filler in the mineral powder or during the leakage process, and no major wear will occur in other positions.

Bucket elevators can bring the convenience of conveying products to production plants in many industries, but use and production require strict requirements to meet the demand. If you want to know more, you can contact us. We are from

Henan Chunying Environmental Protection Equipment Co., Ltd., a factory specializing in the production of lifting machinery, we always welcome your arrival!

.jpg)

.jpg)